The Application of RFID Technology in Automobile Assembly Line

In the traditional automobile assembly line, each assembly line often only assembles the same type of car, so the assembly workers have higher assembly efficiency and are not prone to errors, but now with the continuous development of the automobile manufacturing industry, traditional manufacturing methods and technologies have been Can not meet the manufacturing requirements of modern cars. The diversification and personalization of modern cars require that a car assembly line can assemble different types of cars, so it is necessary to strictly control the data collection work of the car assembly line assembly, and the traditional data collection work mainly relies on manual collection mode or barcode Collection mode, this method has the disadvantages of untimely assembly data collection, low collection efficiency, and large data collection error. To solve this problem, this article proposes to apply RFID technology to the automobile assembly line to achieve the automobile assembly process For the timely and accurate collection of assembly information, the automobile assembly process is information.

1. Introduction(eron intelligent technology co. LTD)

An important indicator of the national manufacturing level is the level of automobile manufacturing. At present, China's traditional automobile manufacturing industry is accompanied by the continuous improvement of China's manufacturing level, which also incorporates many advanced new manufacturing technologies. Therefore, China's level of automobile manufacturing has been greatly improved. At present, an important task and research goal of the automobile manufacturing industry and scientific research workers is to study and promote the manufacturing level of the automobile industry. Although ERP systems have been successfully applied in many enterprises, they have also met some of the processes of automobile manufacturing to a certain extent. Management requirements related to resources, but there are still deficiencies in the management of the automobile production process, such as poor accuracy of data collection, lack of real-time monitoring and traceability of shoveling manufacturing defects, and poor timeliness. Therefore, to perfect the management of the entire automobile manufacturing process, RFID technology should be applied to the automobile assembly line, because if the automobile manufacturing enterprise wants to realize the intelligence and automation of automobile manufacturing, RFID technology is a good method. By introducing this technology in China's automobile manufacturing industry, it can largely solve the problem of certain defects in the monitoring and control information collection of the manufacturing process caused by the application of ERP and other systems in many enterprises, and build China's automobile manufacturing industry into a world-class The automotive industry has gone a step further, and at the same time, it has laid a solid information foundation for the company's after-sales service.

2, RIFD technology overview

(1) The concept of RFID technology

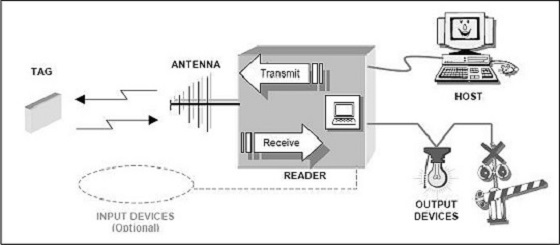

RFID technology is an automatic identification technology, usually people call it radio frequency identification technology or tag identification technology. Its working principle is to write the information into the radio frequency tag through the reader and store it, and then attach the tag to the object, and then transmit the frequency signal of a certain frequency range through the special reader when the information of the object needs to be identified. The radiofrequency tag is guided to send the stored information to the reader, and the information is presented after certain signal processing by the reader. This technique is similar to the barcode scanning technique.

(2) Overview of the development of RFID technology

RFID technology involves a wide range of technologies, including chip technology, data conversion and coding technology, wireless transceiver technology, antenna technology, electromagnetic propagation characteristics, etc. The development of RFID technology is also the common development of these technologies result. Because of the development of these technologies, the variety of RFID hardware products will be more and more abundant, and the performance is also getting better and better, so the application will be more extensive. RFID technology will continue to maintain the momentum of development in the future development, leading RFID hardware equipment such as electronic tags, readers, and readers to make new progress in all aspects.

3, the strategic analysis of RFID technology in the automobile assembly line

The successful application of RFID technology in automobile assembly lines needs to consider the technical feasibility and management aspects, both of which are indispensable. Therefore, this section focuses on analyzing the application strategy of RFID technology in the assembly process of the whole vehicle.

(1) The specific implementation of RFID technology in the automobile assembly line

First of all, on the automobile assembly line that adopts RFID technology, RFID tags are placed on the pallet carrying the body and can move with the pallet, so that a database can be formed, and the database can move with the assembly. The assembly line can be managed according to the production management of the enterprise The needs and assembly process install readers at relevant locations and complete the assembly of the car, while ensuring the accuracy of the assembly.

Second, to enable the reader to read the information in the tag quickly and effectively, the tag should be as standard, reasonable, applicable, and unique as possible, so the coding should be simplified as much as possible to avoid excessive lengthiness. In terms of managing reader code, to better locate the reader, the code of the reader should be combined with the workshop and station information where the reader is located. The capacity of the label installed on the tray is much higher than the barcode, but its capacity is still limited, and when too much information is stored in the label, its reading and writing speed will also be affected, so the information in the label should not Contains assembly information, and assembly information should be obtained by reader assembly code positioning assembly vehicle information, label encoding and industrial information.

Finally, because the development trend of vehicles in a certain period in the future is more personalized and higher quality requirements, the assembly line must avoid various forms of incorrect assembly. Therefore, to verify the correctness of the assembly, in addition to the installation reading at the key station In addition to writers, auxiliary readers should also be installed to help assembly workers identify critical components.

(2) Management specifications of RFID technology in the automobile assembly line

First, the assembler should ensure that when the label is not read, it will not be mixed with metal products or other objects that will affect the label reading and be brought into the reader's reading area, because it will read the writer. Labels have a certain impact, and even lead to failure in reading. Secondly, in the station with key components, the related labels of key components should also be avoided within the working range of the main reader, because this will cause the reader to fail to read the car body labels due to misreading the component labels. Finally, employees are not allowed to bring mobile phones, Bluetooth and other communication devices into the workshop where the RFID system is deployed, because the wireless signals and various electromagnetic waves emitted by these communication devices will interfere with the normal operation of the reader.

4. Conclusion(eron intelligent technology co. LTD)

Based on careful analysis of the application of RFID technology, this article puts forward the suggestion of introducing RFID technology into my country's automobile assembly line, and puts forward the specific implementation strategy of using RFID technology on the automobile assembly line. By introducing RFID technology in data collection, helps enterprises achieve effective management and control of the entire assembly, greatly reduces errors in the assembly process, improves the level of enterprise management, and at the same time realizes the information and network of the automobile assembly process. Reduced the company's operating costs and realized standard and orderly production activities.